Hazelnut Caliber & Size Grading Guide for Food Manufacturers

Hazelnut calibers are one of the most important specifications in industrial procurement. The size of the kernel influences roasting uniformity, chocolate coverage, oil release, flavor development, yield, flow behavior, and downstream processing performance. This guide explains every major caliber group and their ideal applications across chocolate, roasting, bakery, pastes and ingredient manufacturing.

What does “caliber” mean in hazelnut grading?

In the hazelnut industry, caliber refers to the diameter of the kernel measured in millimeters. Calibers determine how uniformly a batch roasts, how it behaves during chocolate enrobing, how much oil it releases during paste production, and how visually consistent the final product appears.

Turkey, the world leader in hazelnut production, uses standardized calibration systems recognized globally by chocolate producers, ingredient processors and importers.

1. Overview of standard industrial calibers

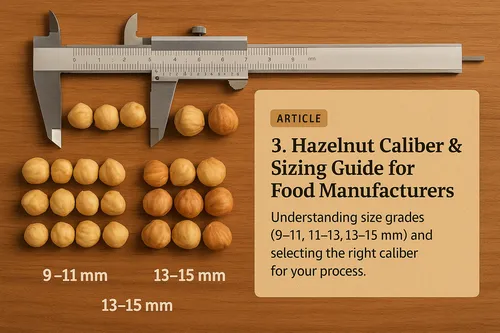

The most common size groups include:

- 9–11 mm: economical grade ideal for chopping, slicing and meal production.

- 11–13 mm: the most widely used size for general manufacturing & roasting.

- 13–15 mm: premium size preferred for whole chocolate inclusions and retail snacks.

- 15+ mm: limited, specialty lots used for high-end whole-nut applications.

The choice of caliber affects not only the appearance of the final product but also weight distribution, batch consistency, and production cost.

2. Why caliber matters for industrial roasting

Roasting performance depends heavily on size uniformity. Larger kernels require more time to develop internal heat penetration, while smaller ones may over-roast or burn if mixed with bigger sizes.

- Smaller calibers (9–11 mm): roast quickly and evenly, ideal for chopped formats.

- Medium calibers (11–13 mm): provide the best balance for flexible production lines.

- Large calibers (13–15 mm): offer superior texture and whole-nut presentation.

For automated roasting lines, consistent calibration increases yield and reduces defect rates.

3. Chocolate applications by caliber

Global chocolate manufacturers often define strict kernel size standards to maintain consistent appearance and enrobing behavior.

- 9–11 mm: used inside filled chocolates, praline centers or for internal grinding.

- 11–13 mm: the most common for whole-nut chocolate fillings and standard bars.

- 13–15 mm: preferred for premium bars where nuts are visibly showcased.

- 15–17 mm: used in artisanal chocolate, luxury assortments and specialty markets.

Larger calibers deliver a higher “nut impact” per bite, especially where visibility matters.

4. Impact on hazelnut paste & praline production

For paste production, size is less important than freshness, oil content and defect levels. However, calibration still influences:

- Roast uniformity prior to milling

- Particle size consistency during refining

- Flavor development from the Maillard reaction

- Oil release behavior impacting viscosity and texture

Many paste manufacturers prefer mixed calibers when cost optimization is required, but premium praline producers often specify uniform sizes for consistent roasting curves.

5. Caliber selection by application

Below is a simplified matching guide:

- Chopping / slicing: 9–11 or 11–13 mm

- Nut mixes & snacks: 11–13 or 13–15 mm

- Premium chocolate: 13–15 or 15+ mm

- Roasting lines: 11–13 mm for balanced heat penetration

- Paste manufacturing: flexible; depends more on quality than size

Choosing the right size improves yield, aesthetics and efficiency across food manufacturing.

6. How exporters calibrate hazelnuts

Modern Turkish processing plants use a combination of:

- Calibrating sieves with precision millimeter spacing

- Optical sorting machines to separate oversized or misshapen kernels

- Manual quality checks for retail-grade or premium lots

- Moisture control systems to ensure consistent roasting behavior

The accuracy of calibration directly affects the stability and performance of the final product—especially in chocolate, roasting and bakery applications.

7. What buyers should specify when ordering

Clear communication ensures correct lot matching. Buyers should specify:

- Caliber range required

- Raw or blanched format

- Moisture target

- Defect tolerances

- Packing format (vacuum, PP, big bag)

- Final application (chocolate, paste, roasting, bakery)

Providing this information helps exporters prepare the optimal quality grade for each use-case.

Need calibrated hazelnut kernels?

Send us your desired caliber, format and application for a tailored offer.